Precision Spindles from FELIN

Felin Machine Tools is a leading company specializing in the development and manufacturing of high-quality spindle systems.

With many years of experience and technical knowledge, we offer innovative solutions to meet the requirements of our customers. Our products help to increase efficiency, precision and productivity and are designed for top performance.

Spindles manufactured by Felin is characterized by its high level of expertise and technological excellence. Our focus is on offering solutions tailored precisely to the individual requirements. Our broad technical expertise exposure gives us an opportunity in manufacturing of spindles for use in various industries and applications.

As a growing company, we place great importance on quality and reliability. We invest in the ongoing training of our team and use state-of-the-art technologies to meet the requirements of the market. Felin stands for technological excellence, problem-solving and innovative strength.

Our top products help our customers to achieve their goals.

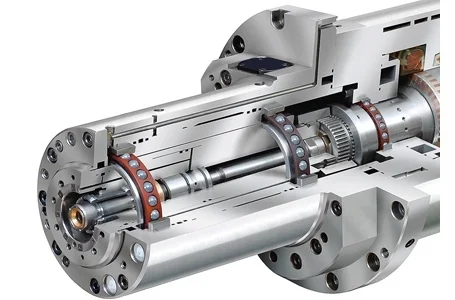

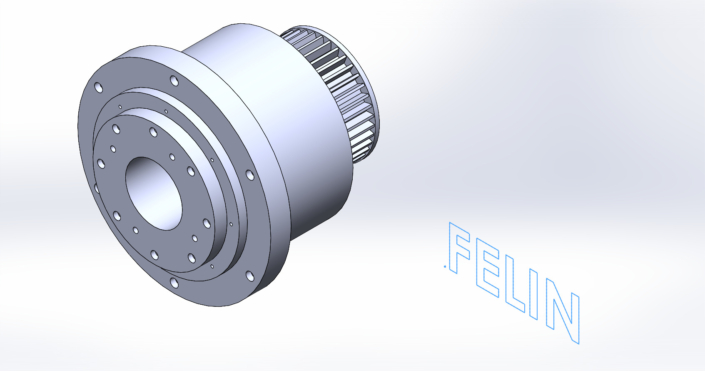

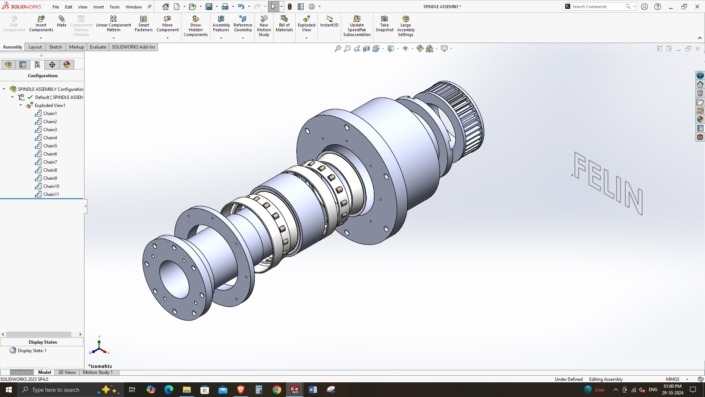

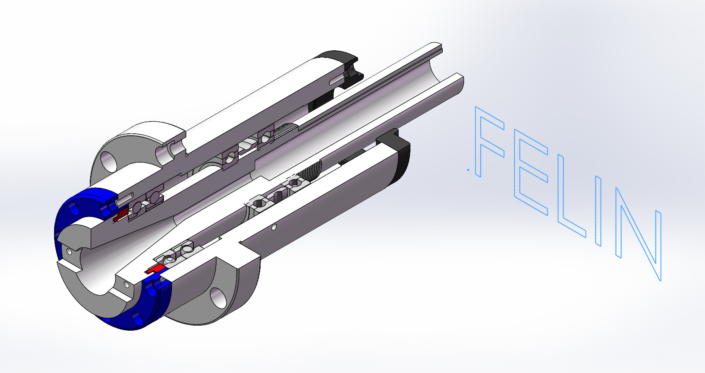

Spindle Design & Manufacturing

We design the spindle in-house with our design engineers and develop with utmost care for the bearing selection, spindle bore selection and various other process.

Only the best materials and components are used for the production of the spindles. We work together with the leading manufacturers of clamping systems to offer you state-of-the-art tool clamping systems.

- Material selection: Choosing the right materials to test the quality of the finished product

- Machining: Using techniques like CNC turning, milling, drilling & grinding to shape metal rods or bars into spindles

- Heat treatment: Applying heat treatments to increase the durability of the spindles guarantee compliance with your quality requirements.

Our assembly staff are regularly trained for the correct use of all components and systems of our suppliers.

Spindle Built Quality

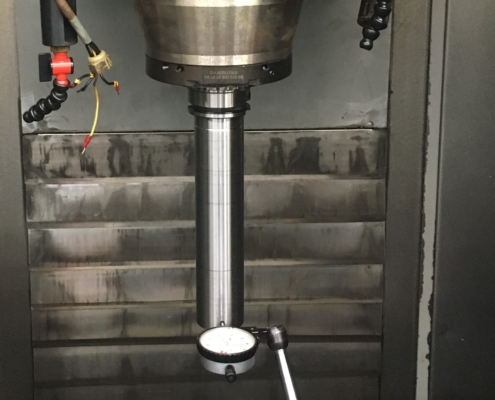

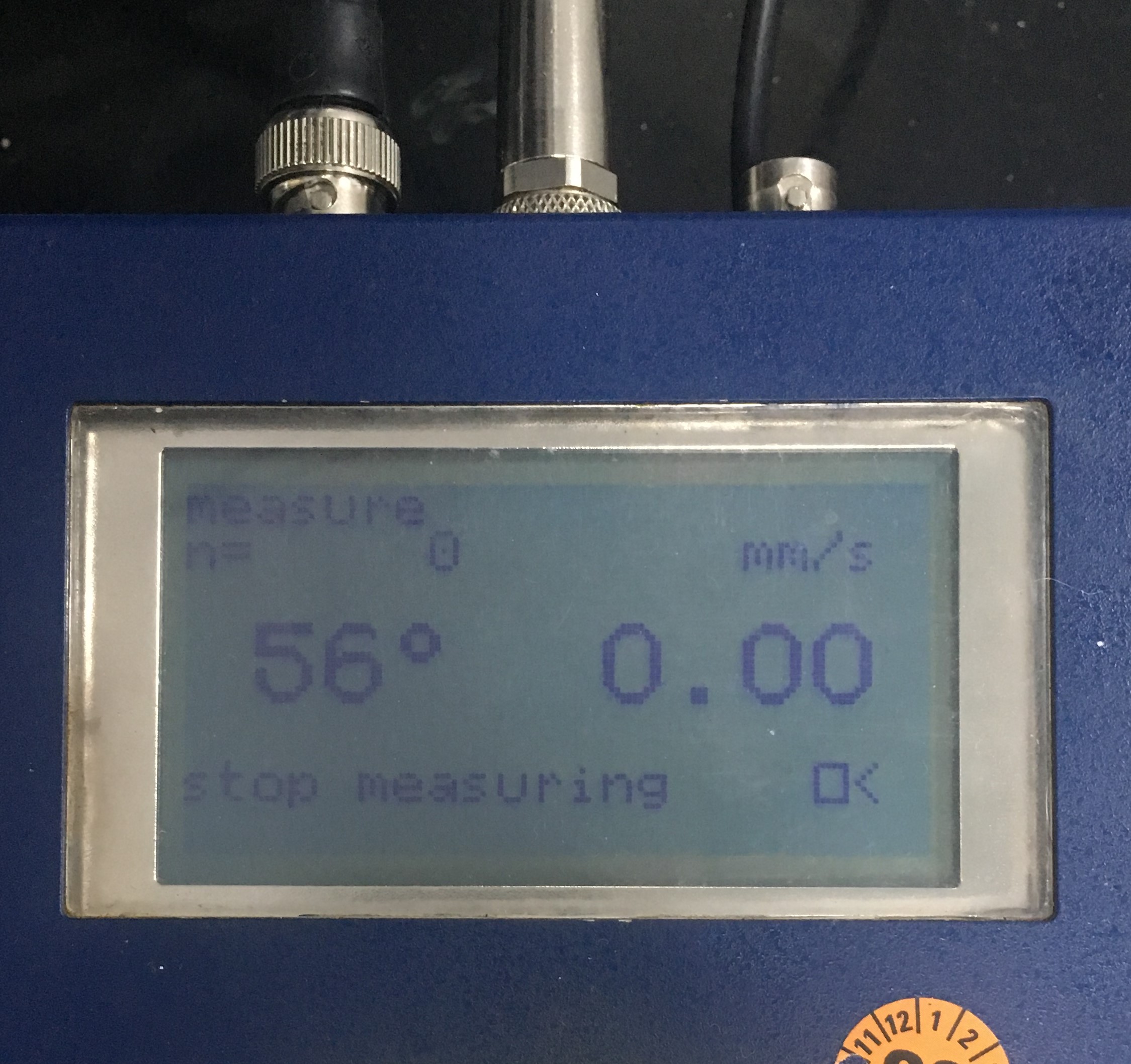

Felin does not just manufacture the spindle for your requirement. But we do 100% inspection with the state of the art equipment’s available with us. Starting from basic equipment like surface table till the high end equipment for spindle balancing and vibration test is available with us.

A spindle build by Felin is carefully handled and assembled by our trained experts. Various inspections are carried out during the spindle assembly. A final assembled spindle is in-house tested and verified before dispatch to customer.

Also we do test the spindles on machine at customer end to check the spindle bearing vibrations and balancing of spindle. This enables the customer to decide the quality of their spindle being used on their machines.

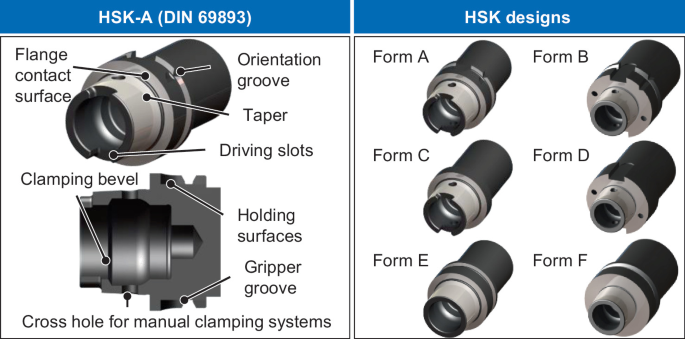

Spindle Tapper

Felin do manufacture variety of spindle tappers. Spindle tappers are selected based on the end application requirement. Selection of spindle tapper plays a major role in the performance of a machine. Below are different DIN/ISO standard spindles being manufactured at Felin.

- HSK A32

- HSK A40 / E40

- HSK A50 / E50

- HSK A63

- HSK A100

- SK / BT 30

- SK / BT 40

- SK / BT 50

- HSK A63

- HSK A100

Bearing Selection

When selecting bearings for any purpose, we ultimately want to be certain of achieving the required level of equipment performance – and at the lowest possible cost. Robustness also is very important because the conditions in which your equipment is assembled, operated and maintained may not be precisely known and may, in fact, vary over time.

In addition to the bearing rating life, there are key factors we consider when putting together the bearing specifications for an application, including:

- Lubricant and supply method

- Shaft and housing fits

- Bearing clearance class

- Cage material and guidance

- Dimensional stability

- Precision requirements

- Bearing sealing

- Mounting method and maintenance

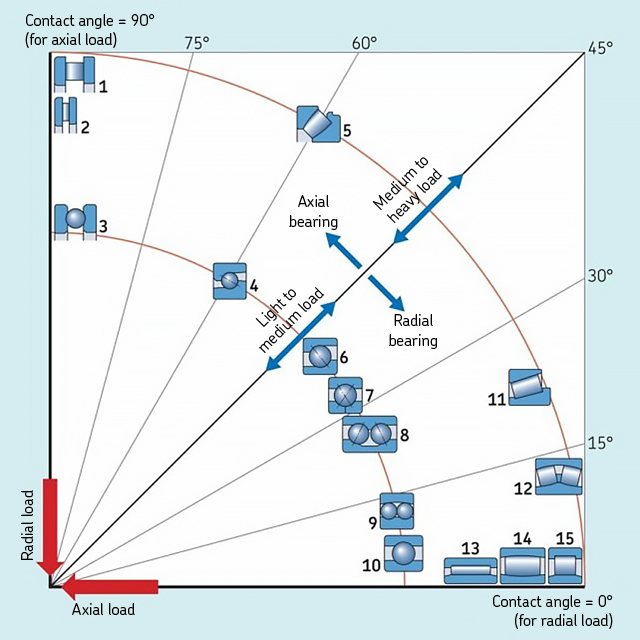

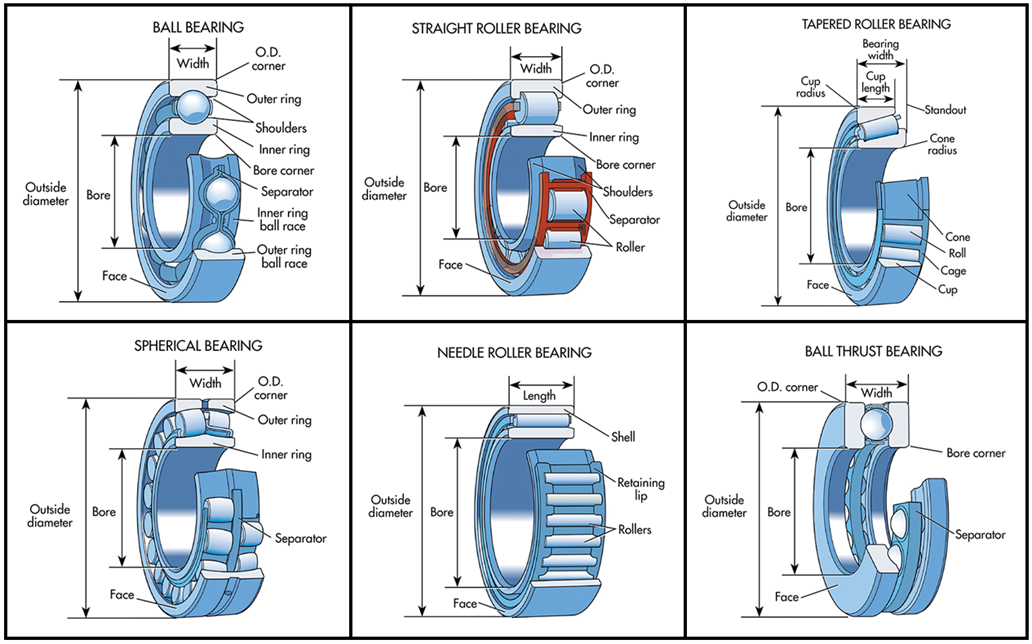

Bearing Type

Each bearing type has characteristic properties that make it more or less suitable for use in a given application. Selection of the main bearing types (including their major features and design variants) and their degree of suitability for certain aspects of use.

Our team with over two decades of experience knows what to consider when selecting a bearing arrangement and the types of bearing to use with it. As per the guidelines of bearing manufacturer, we choose bearing types to satisfy specific demands of an application, such as accommodating available space, loads, misalignment, and more.