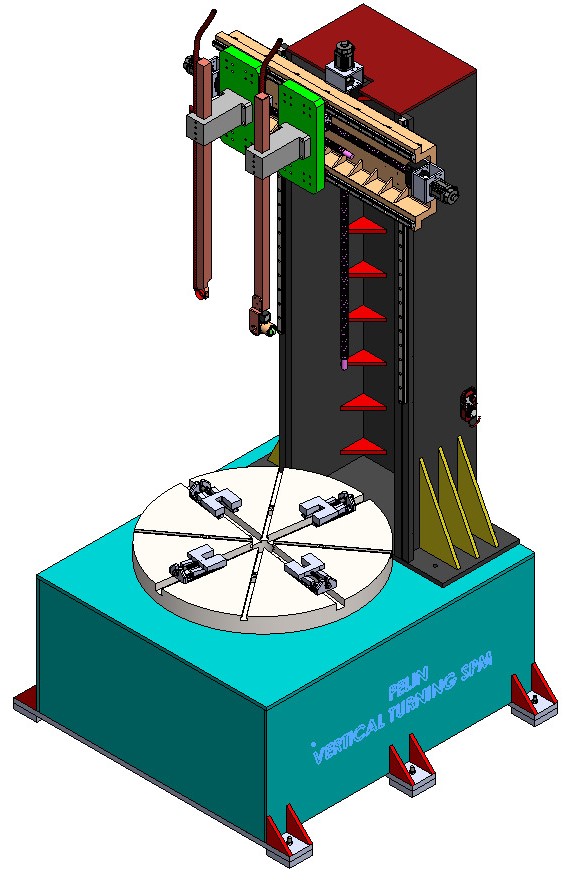

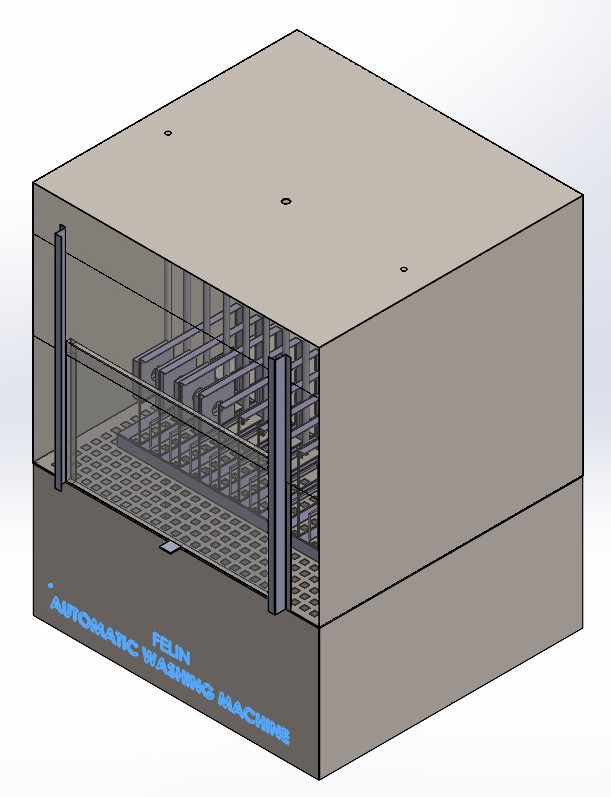

Special Purpose Machines (SPM) / Automation

Designed, Build from quality of Felin

- Design: A well-designed SPM is crucial to ensure product safety and performance.

- Automation: SPMs are advanced versions of manual machinery systems that use limit switches, sensors, logic controls, and automatic job campers to enhance production efficiency.

- Layout: SPMs can be single station or multi station.

Design

A design process is more crucial in SPM. A clear definition of the specific task(s) the machine must perform, including required precision, speed, and reliability will be identified. Further below criteria will be considered in the SPM design.

1. Purpose and Requirements Analysis

2. Customization and Modularity

3. Key Components

4. Automation and Precision Engineering

5. Durability and Safety

6. Testing and Optimization

Felin does the design & manufacturing of SPM as a separate division which compromises design, assembly, testing and commissioning. A specialized team of electrical and mechanical engineers, well trained and experienced professionals handle the assembly of these SPM’s.

Automation

Automation refers to the use of technology to perform tasks with minimal human intervention, enhancing efficiency, accuracy, and consistency in various industries. Automated systems range from simple mechanical devices to complex computer-controlled systems, and they can be applied across manufacturing, logistics, software, and even service industries.

- Control Systems like PLC, Robotics or CNC are carefully selected based on the automation requirements.

- Sensors and feedback devices no to be expensive all the times and few simpler solutions will be more effective than a complex solutions at times.

- Interfaces, Dashboards, Remote monitoring will ease the automation and made for minimal efforts from human or less human intervention.